Constant lubrication of threaded spindles thanks to simalube

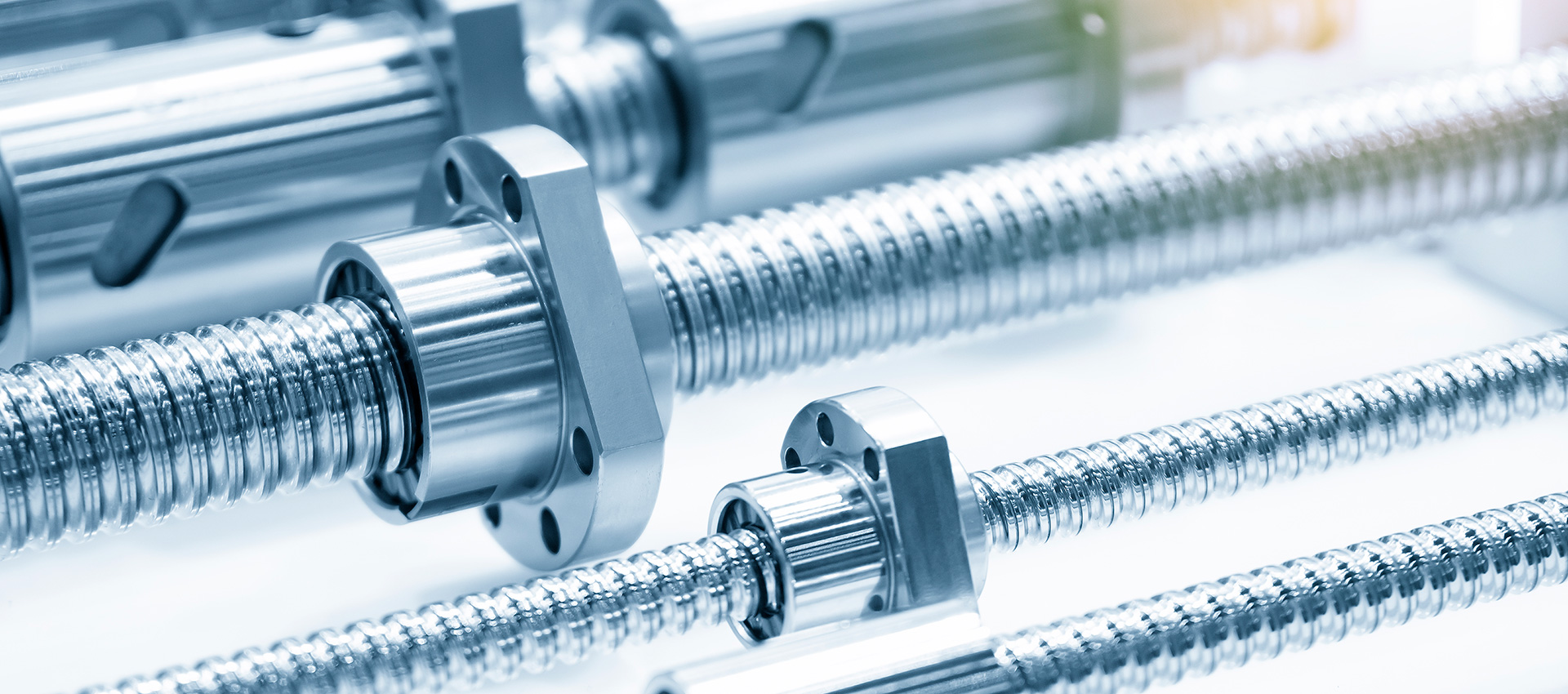

Threaded spindles, sometimes also called drive screws, are machine elements which, together with other elements in a screw drive, serve to convert a rotary movement into a translatory movement.

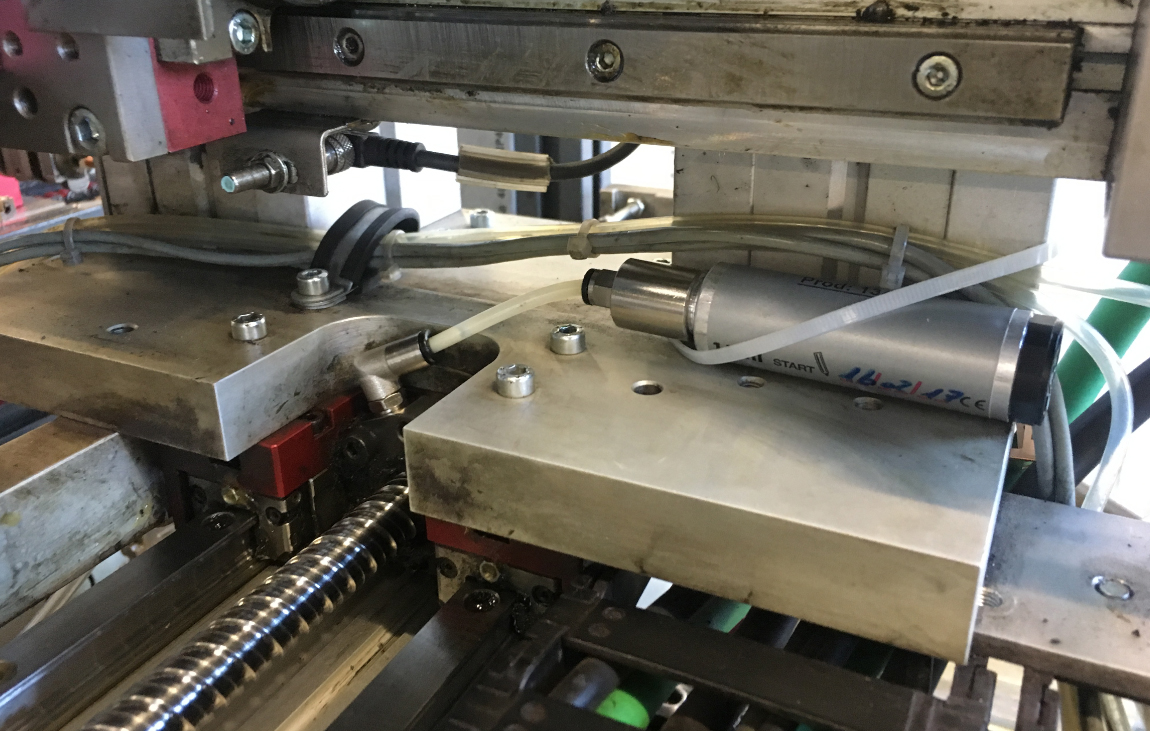

Lubrication points

Challenges

- Environment: pollution, high loads, large forces, high circulation speeds and accelerations

- Installation: little space, very small connection threads

Solution

- The lubricant is applied via a brush or directly to the components

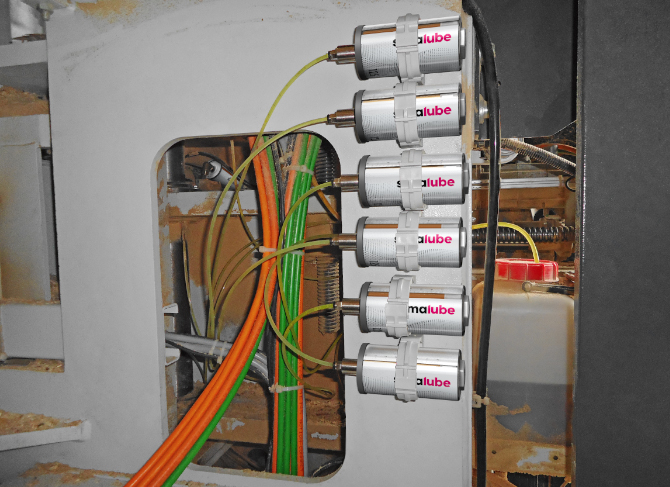

- Direct or indirect assembly. The dispenser is connected directly or via a hose to a brush or directly to the nut of the spindle

Advantages

Advantages of the simalube lubrication system

- Fresh lubricant is continuously supplied

- If the lubricant is continuously supplied in small quantities, much less lubricant is required

- Hard-to-reach lubrication points are reliably supplied with lubricant

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

About the product

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.