Constant lubrication in the automotive industry

One of the world's largest industries is automotive manufacturing. The fierce competition, ever-increasing automation and digitalization demand highly efficient production maintenance. Requirements that are met by the simalube automatic lubricator: It autonomously lubricates production equipment continuously over a period of 1-12 months, significantly reducing plant downtime.

Lubrication points

Challenges

- High demands on the availability of the equipment. simalube lubricant cartridges should be able to be replaced outside the hazardous areas, if possible, so that the equipment does not have to be switched off.

Solution

- simalube lubricant dispenser in the correctly selected size and running time

- simalube IMPULSE connect, easy monitoring and installation via Bluetooth

- Flat brushes for lubrication of chains and guides

- Flat brushes with side connection, for applications in tight spaces

Areas of application and advantages

Benefits of the simalube lubrication system

- Reliable, autonomous lubrication with low maintenance requirements

- Minimal wear of components and thus reduction of maintenance costs

- No unplanned downtime of the equipment due to premature failure of components

Typical installations

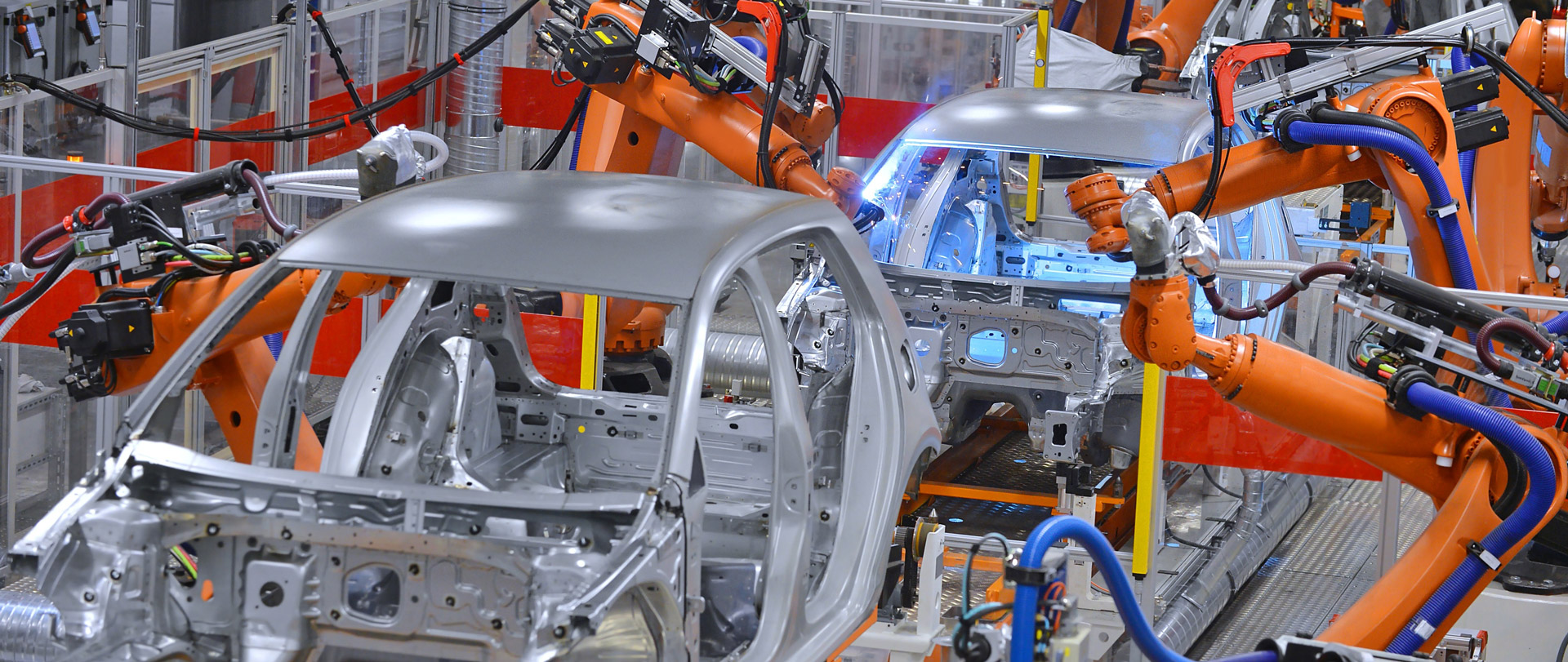

- Robots

- Presses

- Conveyor systems

- Rotary tables

Typical applications

- Chains

- Guides

- Gears

- Pinions

- Rolling bearings

- Rails

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.