Perfect maintenance for chemical plants

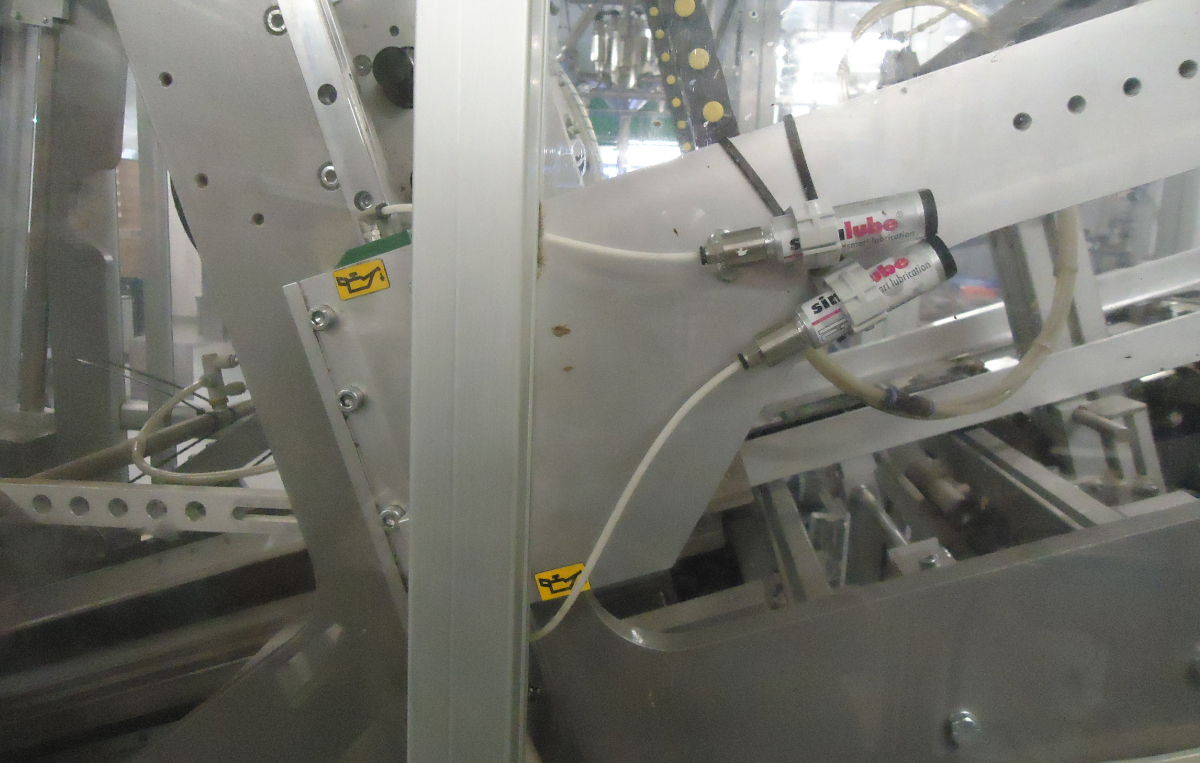

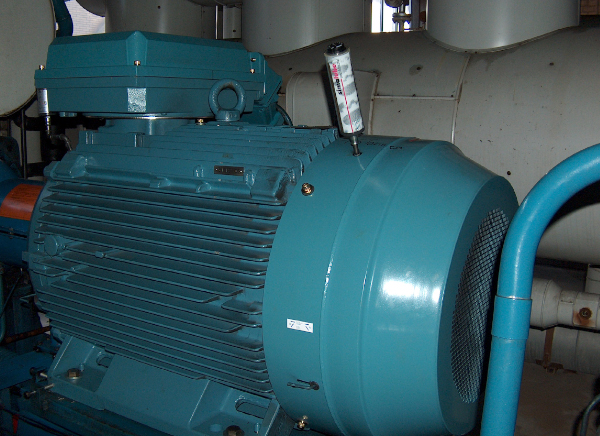

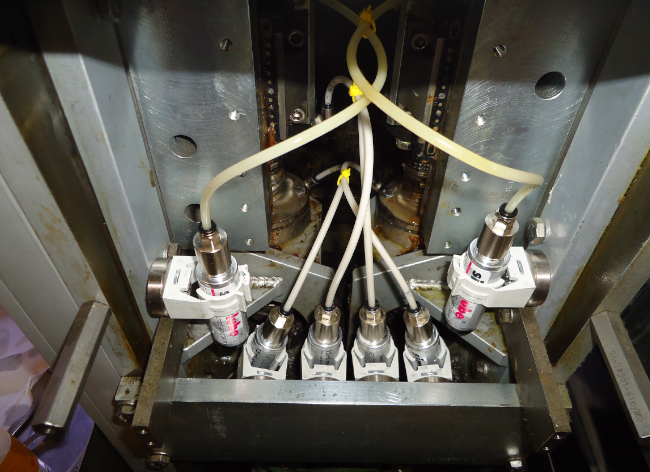

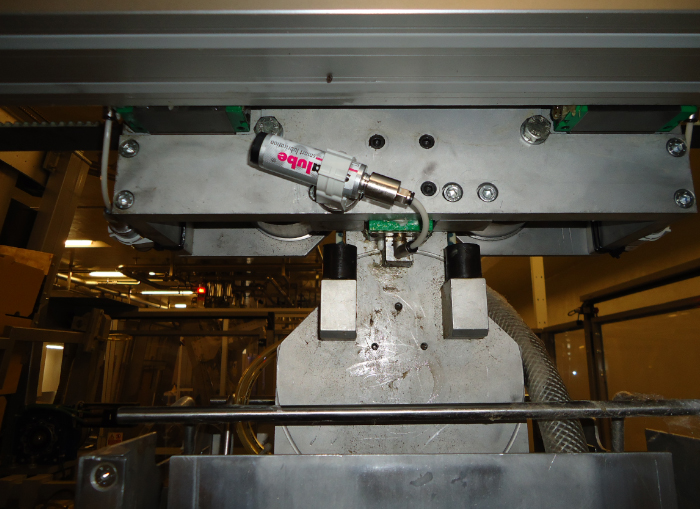

The chemical industry is a highly industrialized branch of industry. With the help of a continuous supply of lubricants from simalube, machine downtimes can be prevented or shortened. This results in efficient and profitable production.

Lubrication points

Challenges

- High demands on the resistance of the products

- The use of approved special lubricants require a product that can be used flexibly

- Use of the products in potentially explosive atmospheres, ATEX.

Solution

- simalube lubricators are in many cases filled with lubricants specially suited for the chemical industry.

Areas of application and advantages

Benefits of the simalube lubrication system

- Reliable, autonomous lubrication with low maintenance requirements

- Long maintenance intervals

- Equipment is lubricated for longer periods of time and does not have to go to the shop for maintenance work and maintenance staff has to visit construction sites less often

Typical installations

- Conveyor belts

- Cranes

- Excavators

- Dump trucks

- Vibrating plates

- Mixers

- Crushers

- Compressors

- Concrete mixers

- Rollers

Typical applications

- Bearings

- Chains

- Guides

- Gears

- Ropes

- Cable drums

- Joints

- Winches

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.