Constant lubrication with simalube in the railway industry

Constant use of rail vehicles leads to increased wear of the flanges and rail flanks due to the friction between wheel and rails. Unwanted squeaking noises are a further unpleasant consequence especially in tight corners. In order to ensure trouble-free rail transport, the individual components in the three areas of depots, vehicles and infrastructure systems must always be optimally maintained - and this under the most varied weather conditions, continuous impact load and vibrations.

Lubrication points

Challenges

- Outdoor applications with large temperature fluctuations

- Vibrations on vehicles

Solution

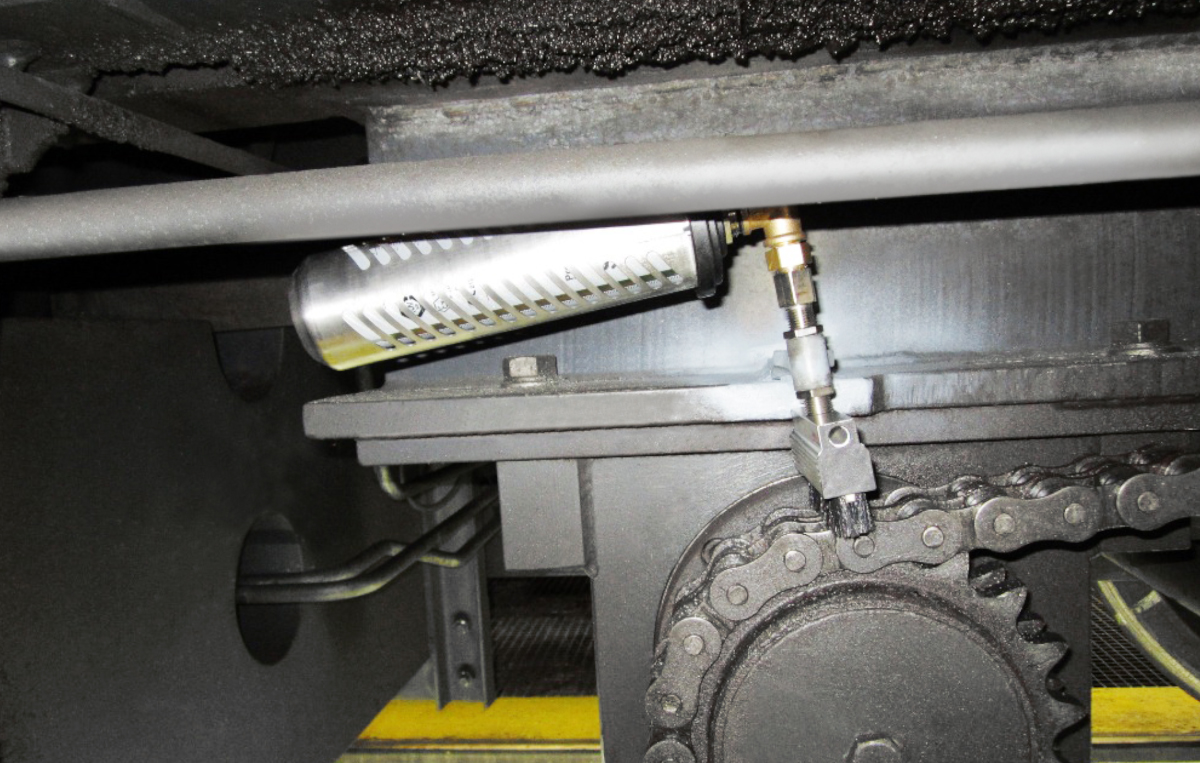

- simalube lubricators with protection against vibrations, often installed remotely

Areas of application and advantages

simalube application areas for railways, subways and trams

- Adjustment of points

- Lifting equipment

- Locking of points

- Gearboxes and motors

- Rails (curves)

- Grinding equipment

- Signal adjustments

- Pantographs

- Buffers

- Chassis

simalube applications for railways, subways and trams

- Bearings

- Pinions

- Gearwheels

- Guides

- Chains

- Couplings

- Spindles

Benefits from automatic lubrication

- Increased operational safety

- Reduced downtime

- Optimization of system availability

- Reduced noise level

- Constant supply of hard to reach lubrication points

Advantages of simalube lubrication systems

- Installation is possible in tight spaces

- Reduction of service costs and maintenance costs: manual lubrication is eliminated, resulting in fewer operations and time saving

- Longer component life thanks to continuous and precise lubrication

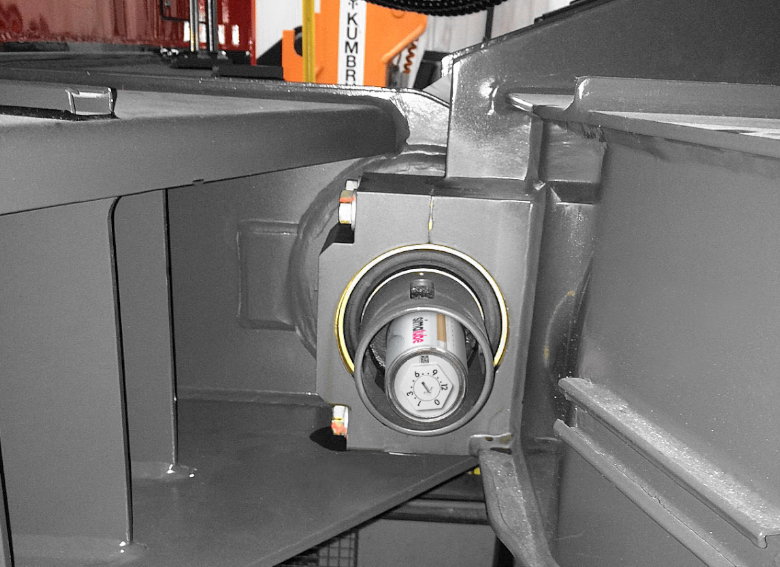

- The progress of the dispensing process can be monitored at any time thanks to the transparent housing (quantity control)

- Reliability: once installed, the lubrication points become reliably supplied with lubricant and will no longer be unattended

- Flexibility: Running times are in nitely adjustable from 1-12 months

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.