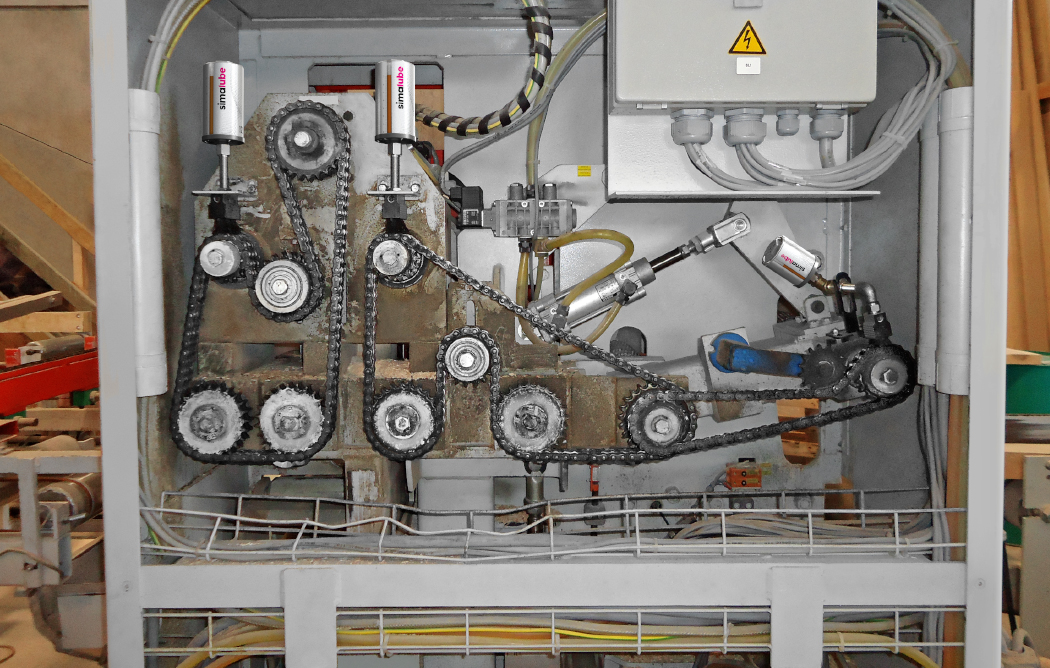

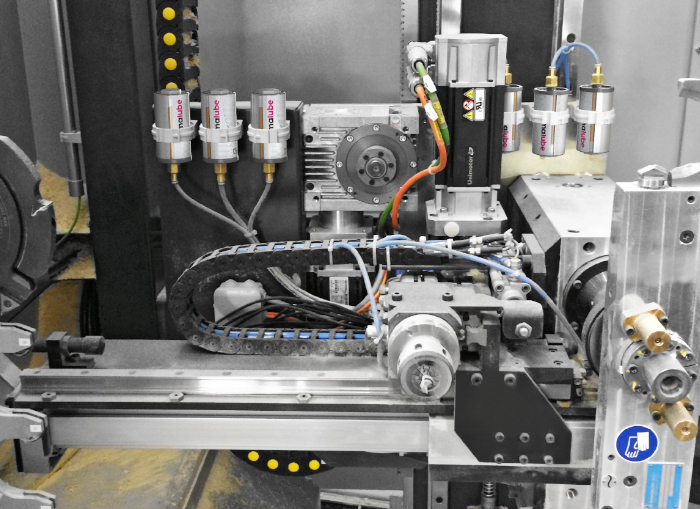

Automatic lubrication in the wood industry thanks to simalube

In wood processing companies, there is often a huge amount of dirt and dust that cause a permanent build-up of dirt on the ball bearing. Early bearing damage can occur that leads to a considerably lower machine output. For this reason, it is particularly important to lubricate the bearings in a reliable, precise manner. The simalube automatic lubricator ensures that the exact amount of lubricant – grease or oil – is applied to the lubrication point, thus avoiding excess or deficient lubrication. Thanks to the hermetically sealed system of the simalube lubricator, dirt is also prevented from penetrating into the roller bearings, thus avoiding bearing damage at an early stage.

Lubrication points

Challenges

- Heavy contamination due to dust and sawdust

- Lubricators must be attached to rotating machine parts

Solution

- simalube grease and oil dispenser

- IMPULSE connect: Digital monitoring and configuration of lubrication points via Bluetooth®. The device can be used to increase the pressure up to 10 bar.

Areas of application and advantages

simalube applications in the wood processing industry

- Conveyor systems/chains

- Vibration channels

- Track rollers

- Trimming systems/chipping systems

- Loading cranes

- Drives/motors

- Saws of all types Spindles/ducts

- Debarking systems

- Transportation systems

Further benefits

- Reliability: Once installed, the lubrication points are reliably lubricated and never forgotten

- The hermetically sealed system prevents contamination by dust and debris (IP68)

- Reduction of service requirements and maintenance costs: Manual lubrication is no longer necessary meaning fewer disruptions and a huge saving of time

- Longer service life of machines thanks to continuous and accurate lubrication

- Flexibility: The running time is adjustable from 1–12 months

- No need to shut down the machines during maintenance

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.